Water Spray Nozzles

Price 5000.00 INR/ Piece

Water Spray Nozzles Specification

- Noise Level

- Silent

- Condition

- New

- Material

- Stainless Steel / Brass / Plastic

- Dimensions

- Varies (Standard Sizes)

- Configuration

- Threaded / Flanged

- Mute

- Yes

- Driven Method

- Manual / Line Pressure

- Working Presssure

- 3 to 10 Bar

Water Spray Nozzles Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Water Spray Nozzles

We offer the premium quality Water Spray Nozzles. The product is designed with the use of latest engineering applications for the standout performance. It prays very fine mist of water for cooling and also can be used as chamber humidifier. The product is capable of variable water flow and air floor as well as throw of spray. We have made the product from stainless steel for the longer and durable life. The Water Spray Nozzles are available at a very reasonable price.

Main features:

- Usable for various applications

- High efficiency and performance

- Corrosion resistant

Versatile Material Choices

Our water spray nozzles are fabricated in stainless steel, brass, or plastic to match diverse operational environments and media types. Each material ensures corrosion resistance and longevity, making these nozzles suitable for a wide range of industries and applications.

Flexible Mounting Options

Choose between threaded or flanged configurations to seamlessly integrate with your existing system. Multiple standard sizes simplify installation while maintaining compatibility and robust sealing for leak-free operation.

Silent Performance

Designed with mute technology, these spray nozzles operate silently, meeting the noise requirements for sensitive settings such as laboratories or food processing facilities. The quiet function minimizes workplace distraction and maintains a calm environment.

FAQs of Water Spray Nozzles:

Q: How are water spray nozzles installed in a piping system?

A: Installation depends on the configuration you select. Threaded nozzles can be screwed directly onto compatible fittings, while flanged nozzles require bolting onto a matching flange. Ensure that the mounting method matches your systems specifications for secure and leak-free performance.Q: What is the benefit of choosing a silent, mute water spray nozzle?

A: Silent or mute water spray nozzles significantly reduce noise disruption, making them ideal for environments where low sound levels are essential, such as hospitals, research labs, and food processing plants.Q: When is it recommended to use stainless steel versus brass or plastic nozzles?

A: Stainless steel nozzles are best for harsh or corrosive conditions, brass offers good durability for general use, and plastic is suitable for non-corrosive, lightweight applications. Selecting the right material improves lifespan and performance based on your operating environment.Q: Where can these water spray nozzles be used effectively?

A: They are suitable for a variety of settings including industrial cooling systems, fire protection, dust suppression, and cleaning processes, as well as any application requiring controlled water spray at moderate pressures.Q: What is the process for selecting the correct nozzle configuration and size?

A: Evaluate your systems working pressure, required spray pattern, material compatibility, and mounting method (threaded or flanged). Consulting with a supplier helps ensure the nozzle matches your applications technical requirements.Q: How does the manual or line pressure-driven operation work?

A: Manual operation allows the nozzle to be activated as needed, while line pressure-driven models automatically spray when the system reaches the designated pressure (3 to 10 bar), providing flexible use according to process needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Nozzle Category

Real Blow Nozzle

Price 3400.00 INR / Piece

Minimum Order Quantity : 80 Pieces

Noise Level : 99 db

Configuration : Nozzle with manual handle

Mute : No

Dimensions : Length 300 mm x Diameter 60 mm

High Thrust Nozzle

Minimum Order Quantity : 5 Pieces

Noise Level : <80 dB

Configuration : Standard & Custom

Mute : No

Dimensions : Length: 110mm, Nozzle Diameter: 15mm

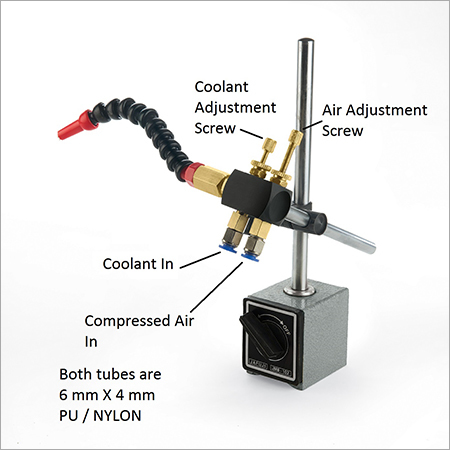

Coolant Spray Nozzle CSN-07

Price 12000.00 INR / Piece

Minimum Order Quantity : 15 Pieces

Noise Level : Below 70 dB

Configuration : Single Nozzle

Mute : No

Dimensions : Head OD 16 mm x Length 65 mm (Approx.)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free