High Thrust Nozzle

High Thrust Nozzle Specification

- Noise Level

- <80 dB

- Power Consumption

- Low

- Air Discharge

- Concentrated Stream

- Condition

- New

- Material

- Aluminum Alloy

- Power Source

- Electric / Air Driven

- Voltage

- 220V 415V

- Dimensions

- Length: 110mm, Nozzle Diameter: 15mm

- Lubrication Type

- Oil-Free

- Configuration

- Standard & Custom

- Mute

- No

- Air Flow Capacity

- High Flow

- Driven Method

- Pneumatic

- Working Presssure

- 6 10 bar

- Motor

- Electric Motor Compatible

- Corrosion Resistance

- Yes

- Color

- Silver or As Requested

- Usage

- Industrial Blowing, Drying, Cleaning

- Spray Angle

- Standard / Wide

- Mounting Type

- Threaded / Flange

- Maintenance

- Low / Easy to Clean

- Temperature Resistance

- Up to 120°C

- Connection Size

- 1/4" to 2" BSP/NPT

High Thrust Nozzle Trade Information

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About High Thrust Nozzle

Having complete knowledge of the domain, we are engaged in manufacturing and supplying an exceptional range of High Thrust Nozzle. It provides a high thrust, concentrated stream of high velocity airflow for blow off, cooling, drying and cleaning applications. The sound level is extremely low and air consumption is minimal. The compressed air is ejected through holes located in recessed grooves that cannot be blocked or dead ended. Under the supervision of experts, this High Thrust Nozzle is stringently checked on various parameters to ensure hassle free functioning at clients end.

Features:

- Minimal air consumption

- Negligible maintenance

- Concentrated, high velocity airstream

- It delivers air blow by applying high force

- It adopts stainless steel made nozzle

- It can deliver medium piercing blow

- This blow gun works at minimal consumption of compressed air

- It requires 14 CFM air for its operation

- Thrust: 340 gms 300 mm

- It generates 99 decibel noise

Specification

- Air amplification upto 3 times.

- Lower noise level. High Thrust. u

- Meet s international safet y norms.

- Repairable Stainless nozzle. u

- Air Consumption 14 SCFM. Thrust : 340 gms. 300 mm, 99 db.

Wide Range of Industrial Applications

The High Thrust Nozzle offers exceptional versatility, serving various industrial sectors for blowing off debris, drying surfaces, and industrial cleaning requirements. Its compatibility with both electric and air-driven systems makes it a suitable choice for new installations and equipment upgrades alike.

Resilient and Efficient Design

Manufactured from aluminum alloy and boasting corrosion resistance, this nozzle maintains consistent performance in challenging industrial settings. Its easy-to-clean, oil-free design ensures low maintenance, while concentrated air discharge delivers effective results with minimal power consumption. Multiple mounting and connection options further enhance installation flexibility.

FAQs of High Thrust Nozzle:

Q: How do I install the High Thrust Nozzle onto my existing system?

A: Installation is straightforward as the nozzle supports both threaded and flange mounting types. You can connect it to 1/4" to 2" BSP/NPT fittings. Ensure the system is depressurized before mounting the nozzle to maintain safety.Q: What industrial processes benefit most from using this nozzle?

A: This nozzle is ideal for blowing, drying, and cleaning processes where a concentrated, high-flow air stream is needed. It performs efficiently in manufacturing, assembly, food processing, and equipment maintenance environments.Q: When should I use the standard versus wide spray angle option?

A: Choose the standard spray angle for focused cleaning or drying tasks that require efficient removal of debris or moisture. The wide spray angle is better suited for covering larger surfaces or delicate materials that need gentle air distribution.Q: Where can this nozzle be used given its operating temperature and pressure ranges?

A: With a temperature resistance up to 120C and working pressure range of 6 to 10 bar, this nozzle is suitable for most industrial environments, including workshops, factories, and production lines exposed to heat or pressurized air systems.Q: What benefits does the oil-free, low-maintenance design offer?

A: The oil-free configuration reduces the risk of contaminating sensitive products and simplifies maintenance. Its easy-to-clean surface minimizes downtime and ensures consistent performance over time.Q: How is noise control managed during operation?

A: Even under high flow capacity, the nozzle operates at a noise level below 80 dB, ensuring a safer and more comfortable working environment compared to traditional models.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Nozzle Category

Real Blow Nozzle

Price 3400.00 INR / Piece

Minimum Order Quantity : 80 Pieces

Noise Level : 99 db

Working Presssure : Up to 6 Bar

Configuration : Nozzle with manual handle

Material : Stainless steel

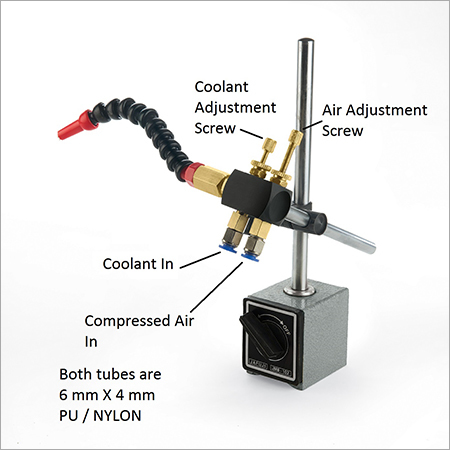

Coolant Spray Nozzle CSN-07

Price 12000.00 INR / Piece

Minimum Order Quantity : 15 Pieces

Noise Level : Below 70 dB

Working Presssure : 37 bar

Configuration : Single Nozzle

Material : Brass Body with Copper Nozzle

Water Spray Nozzles

Price 5000.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Noise Level : Silent

Working Presssure : 3 to 10 Bar

Configuration : Threaded / Flanged

Material : Stainless Steel / Brass / Plastic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free