Straight Valve Adopts QC fittings

Price 200 INR/ Piece

Straight Valve Adopts QC fittings Specification

- Noise Level

- Low

- Air Discharge

- Controlled via Valve

- Condition

- New

- Material

- Brass with Chrome Plating

- Dimensions

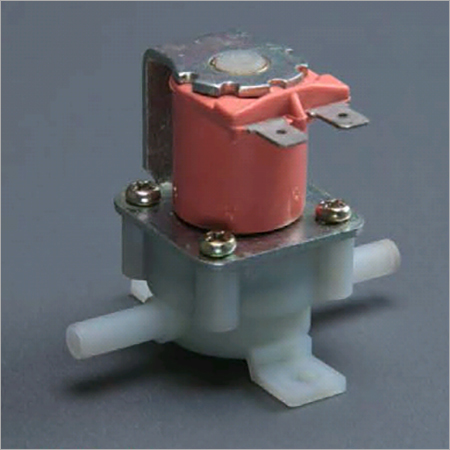

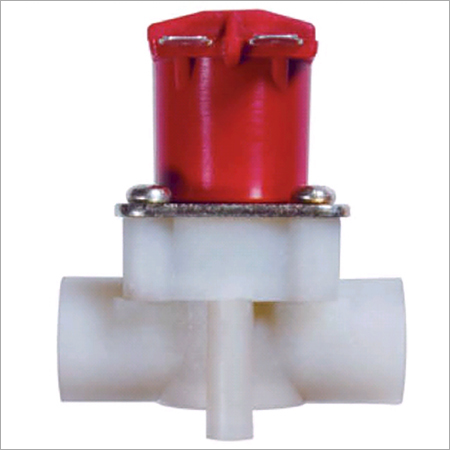

- Standard Size, Refer Image

- Configuration

- Straight Valve with QC Fittings

- Mute

- Yes

- Driven Method

- Manual Operation

- Working Presssure

- 10-16 Bar

- Surface Finish

- Chrome Plated

- Application

- Compressed Air, Pneumatic Systems

- Valve Type

- Straight

- Connection Type

- Quick Connect (QC) Fittings

- Installation

- Inline

- Handle Material

- Plastic/Polymer

- Temperature Range

- -10°C to 80°C

- Usage

- Industrial, Workshop

- Seal Material

- Nitrile Rubber (NBR)

- Pressure Rating

- Up to 16 Bar

- Corrosion Resistance

- Yes

Straight Valve Adopts QC fittings Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Straight Valve Adopts QC fittings

These Straight Valve Adopts QC Fittings have no internal valves, providing maximum flow with minimum pressure drop. The offered fittings can be operated by hand, and these quick connect fittings replace threaded or flanged connections, which require wrenches. These save time and effort to connect or disconnect the line and are highly convenient method adopted now a day. Manufactured using best quality materials and latest machines, these Straight Valve Adopts QC Fittings are highly appreciated in the market. Besides, these fittings are available in different standard sizes.

Features:

- Dimensional accuracy

- Simple installation

- Supreme finish

Effortless Quick Connect Installation

The valve incorporates Quick Connect (QC) fittings, allowing for fast and secure integration into pneumatic and compressed air systems. The inline design simplifies the installation process, reducing downtime and making maintenance more convenient. Its standard size ensures compatibility with common air line setups.

Reliable Performance and Safety

Built to withstand pressures up to 16 bar and temperatures from -10C to 80C, this straight valve delivers consistent and safe operation. The chrome-plated brass material resists corrosion, while nitrile rubber seals help prevent leaks, providing longevity in demanding industrial or workshop conditions.

Controlled Air Flow for Industrial Applications

Engineered for manual operation, the valve enables precise regulation of air discharge, supporting various pneumatic tools and machinery. The mute feature ensures quiet performance, which helps reduce noise pollution in busy work environments, thereby enhancing user comfort and safety.

FAQs of Straight Valve Adopts QC fittings:

Q: How do I install the straight valve with Quick Connect fittings in my pneumatic system?

A: Installation is straightforward thanks to the inline configuration and QC fittings. Simply insert the valve into your air line, ensuring it matches standard size requirements. Press the QC connectors firmly to achieve a secure and leak-resistant connection.Q: What are the benefits of using this valve in industrial or workshop applications?

A: This valve provides reliable corrosion resistance due to its chrome-plated brass body, controlled and quiet air discharge, and easy manual operation. These features help maintain safe working conditions and reduce maintenance needs over time.Q: Where is this straight valve typically used?

A: The valve is ideal for compressed air and pneumatic systems found in industrial settings, manufacturing plants, workshops, and similar environments in India.Q: What is the pressure rating and temperature tolerance of this valve?

A: The valve is suitable for working pressures between 10 and 16 bar, and can withstand temperatures from -10C to 80C, making it suitable for a range of climatic conditions and demanding applications.Q: Which materials are used for the handle and sealing components of the valve?

A: The handle is made from plastic or polymer to provide insulation and durability, while the seals are constructed from nitrile rubber (NBR) for effective leak prevention and longevity.Q: Can I use this valve for new compressed air installations?

A: Yes, the valve is supplied in new condition and adheres to standard dimensions, making it suitable and compatible for both new setups and replacements in existing pneumatic systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Solenoid valves Category

Straight magnetically latching valve

Price 350 INR / Piece

Minimum Order Quantity : 10 Pieces

Dimensions : Varies as per model (e.g., 45 x 25 x 21 mm)

Mute : Yes

Condition : New

Configuration : Straight (inline)

Ro System Inside Threaded Solenoid Valve

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimensions : About 60mm x 22mm x 40mm

Mute : Yes

Condition : New

Configuration : 2 Way Normally Closed

1/2 Threaded Valve

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimensions : 1/2 BSP Thread

Mute : Yes

Condition : New

Configuration : Single Unit

Domestic Ro Straight Qc Valve

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimensions : Approx. 4 cm length

Mute : Yes

Condition : New

Configuration : Straight QC Valve

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS