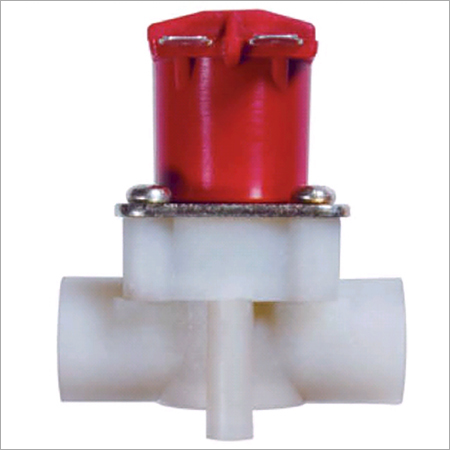

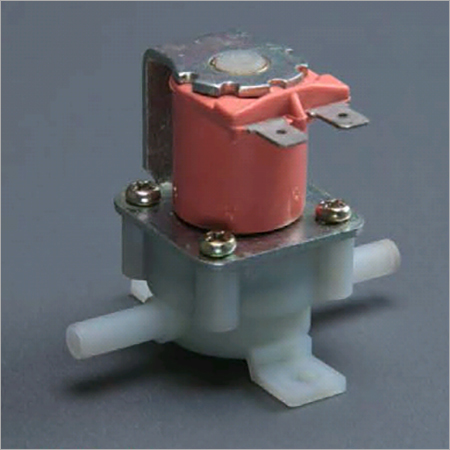

Straight magnetically latching valve

Price 350 INR/ Piece

Straight magnetically latching valve Specification

- Power Consumption

- <1.6W

- Noise Level

- Low (<50 dB)

- Air Discharge

- Supports both inlet and outlet air flows

- Condition

- New

- Material

- High Quality Engineering Plastics & Copper

- Power Source

- Electric

- Voltage

- DC 12V / 24V (other options available)

- Dimensions

- Varies as per model (e.g., 45 x 25 x 21 mm)

- Lubrication Type

- Oil-Free

- Configuration

- Straight (inline)

- Mute

- Yes

- Air Flow Capacity

- Varies as per model (typically up to 500 L/min)

- Driven Method

- Electromagnetic

- Working Presssure

- 0.02-0.8 MPa

Straight magnetically latching valve Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Straight magnetically latching valve

Straight Magnetically Latching Valve uses a permanent magnet within the solenoid. To shift the valve from one state to another, a short millisecond DC voltage is applied to the coil. To shift the valve back, a reverse polarity pulse is applied to the coil. This feature makes this valve suitable for use in remote areas where continuous power may be limited. Straight Magnetically Latching Valve is also valuable in equipment where coil heating, due to a continuous application of power, is undesirable such as in medical and chemical analyzers.

Features:

- Withstand adverse conditions

- Low maintenance

- Easy to install

Efficient Magnetic Latching Technology

This valve incorporates magnetically latching technology, ensuring rapid switching and stable operation with minimal power consumption (<1.6W). Its durable coil insulation (Class B or better) and electromagnetic driving method deliver consistent reliability over prolonged use in industrial environments.

Versatile Mounting and Compatibility

Offering direct or inline mounting options, the valve can be seamlessly integrated into a multitude of setups. With standard port sizes (1/8 or 1/4 BSP/NPT), it accommodates a wide array of pneumatic systems, making it adaptable across diverse industries in India.

Noise Reduction and Oil-Free Design

Engineered to operate below 50 dB, this valve supports quiet processes, ideal for noise-sensitive applications. Its oil-free lubrication reduces maintenance needs and aligns well with clean-room requirements, promoting longer service life and environmental compatibility.

FAQs of Straight magnetically latching valve:

Q: How does the magnetically latching solenoid valve operate?

A: The valve uses an electromagnetic coil to magnetically latch the actuator, allowing rapid switching of air or neutral gases with minimal energy use. It remains in position without continuous power, enhancing energy efficiency.Q: What media can be used with this valve?

A: This valve is suitable for air and neutral gases, making it ideal for pneumatic automation systems and laboratory setups requiring clean and stable fluid control.Q: What are the installation options for this valve?

A: The valve supports direct or inline mounting, enabling flexible installation within various piping configurations. Standard BSP and NPT port sizes allow compatibility with most system designs.Q: When is it recommended to choose NBR or EPDM sealing material?

A: NBR is preferred for general-purpose air applications, while EPDM offers enhanced chemical and temperature resistance, making it suitable for specialized environments with harsher media.Q: Where can this valve be sourced in India?

A: Manufacturers and authorized suppliers across India offer this valve, providing new, high-quality products for industrial automation, pneumatics, and process control sectors.Q: What is the process for electrical connection in this valve?

A: Depending on the model, electrical connection options include lead wire or standard connectors, enabling straightforward integration with control panels or automation systems.Q: What benefits does the mute, oil-free design provide?

A: The oil-free lubrication and low noise level (<50 dB) reduce maintenance needs and contribute to a cleaner working environment, making the valve particularly suitable for sensitive or hygienic applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Solenoid valves Category

Threaded Straight Bistable Latching Solenoid Valve

Price 350 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Brass body, Stainless Steel internals, NBR seals

Noise Level : Low

Dimensions : Approx. 65mm x 25mm x 55mm

Condition : New

1/2 Threaded Valve

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Brass

Noise Level : Low

Dimensions : 1/2 BSP Thread

Condition : New

Straight Valve Adopts QC fittings

Price 200 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Brass with Chrome Plating

Noise Level : Low

Dimensions : Standard Size, Refer Image

Condition : New

Farm Irrigation Female Threaded Valve

Price 3500 INR

Minimum Order Quantity : 1 Piece

Material : High Quality Polypropylene (PP)

Noise Level : Silent Operation

Dimensions : 1 inch, 1.5 inch, 2 inch (available sizes)

Condition : New

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free