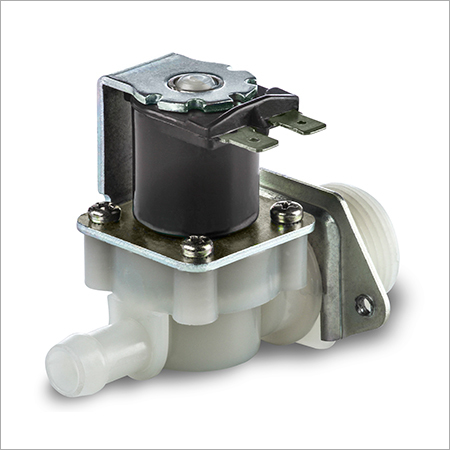

Inlet or Feed valves

Price 5000 INR/ Piece

Inlet or Feed valves Specification

- Air Discharge

- Controlled via Outlet

- Noise Level

- Below 20 dB

- Condition

- New

- Material

- Brass/SS/Plastic

- Dimensions

- Varies by Model (Standard: 1/2 to 2 BSP)

- Lubrication Type

- Maintenance-Free

- Configuration

- Inline Installation

- Mute

- Yes

- Driven Method

- Manual or Automatic

- Working Presssure

- Up to 10 Bar

Inlet or Feed valves Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Inlet or Feed valves

- Outlet : 10.5 mm, 12.5 mm,1/4" BSPM

- Inlet : 3/4" BSPM

- Mounting : Mounting Bracket (Optional)

- Food Contact : On request

- Flow rate: 1.5 / 2.5 / 5 / 10 / 30 LPM

- Inlet Filter: Polyacetal, 0.45 mm

- Available Valve Type : Normally Closed (0.2 to 8 bar), Normally Open (0.2 to 3 bar), Low Pressure (600 mm WC), Magnetically Latching (0.2 to 6 bar)

- G series : Normally Closed 6 V DC*, 12, 24, 36, 48 V DC, 110 V*, 230 V AC

- N Series : Normally Open 12, 24, 36, 48 V DC

- L Series :Magnetically Latching: 6- 12 V DC, 60 mS, 9 Ohms.

- D Series : Low pressure direct acting, 12, 24, 36, 48 V DC, 230 V AC

Versatile Media Compatibility

Designed to handle liquids and gases, these inlet and feed valves are a practical choice for controlling water, oil, gas, and air flow. The use of multiple seal materials such as NBR, PTFE, and silicone ensures chemical compatibility and longevity across different applications.

Flexible Installation Options

Install easily on a variety of systems with threaded (BSP/NPT) or flanged end connections. Valves are available in multiple port sizes (1/2 to 2 inches) and suit both horizontal and vertical mounting positions. Polished or coated finishes and various handle types offer both aesthetics and customizability.

Engineered for Reliability and Silence

Each valve is built for quiet operation, maintaining noise levels below 20 dB and featuring a maintenance-free lubrication design. Their robust construction is ready for challenging environments, tolerating temperatures from -10C to 120C and pressures up to 10 bar, all while managing precise airflow or fluid delivery.

FAQs of Inlet or Feed valves:

Q: How do I select the correct inlet/feed valve for my application?

A: Choose your valve based on the media (water, oil, gas, or air) you need to handle, the required connection type (threaded BSP/NPT or flanged), and appropriate port size (from 1/2 to 2 inches). Also consider operating temperature range, working pressure, and seal material (NBR, PTFE, or silicone) for optimal compatibility and performance.Q: What benefits do the noise-reduction features of these valves offer?

A: These valves are designed for exceptionally quiet operation, maintaining noise levels below 20 dB. This contributes to a more comfortable and safer environment, especially in noise-sensitive industrial or commercial settings, without compromising efficiency.Q: When should I use a maintenance-free inlet or feed valve?

A: Maintenance-free valves are especially advantageous in hard-to-access or continuous-operation systems where routine upkeep would be challenging. Their self-lubricating design reduces downtime and maintenance costs, making them suitable for new installations requiring reliable long-term performance.Q: Where can these valves be installed in my system?

A: These valves are suitable for inline installation in both horizontal and vertical positions. Their adaptability, with multiple mounting orientations and compatible end connections, makes them ideal for varied piping setups in commercial, industrial, or utility infrastructure.Q: What process is involved in controlling air discharge through these valves?

A: Air discharge is managed precisely via the outlet, ensuring controlled and safe evacuation as needed. The design allows for exact regulation of flow rate, supporting customization based on the demands of each specific application.Q: How does the chosen seal material affect the valves performance?

A: Each seal materialNBR, PTFE, or siliconeis selected for its resistance to particular fluids and temperatures. This ensures reliable operation with your chosen media, prevents leaks, and extends service life under varied pressure and temperature conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Solenoid valves Category

I-10F-M-F Solenoid Valve

Price 1500 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Brass Body with Nitrile Rubber Seal

Condition : New

Mute : Yes

Configuration : 2/2 Way, Normally Closed

Whirlpool Washing Machine Inlet Solenoid Valve

Price 200 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Highgrade Plastic with Copper/Electronic Coil

Condition : Other, Brand New

Mute : Yes

Configuration : 2 Way Inlet Valve

Farm Irrigation Female Threaded Valve

Price 3500 INR

Minimum Order Quantity : 1 Piece

Material : High Quality Polypropylene (PP)

Condition : New

Mute : Yes

Configuration : 2way

Straight Threaded Valve

Price 200 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Brass

Condition : New

Mute : Yes

Configuration : Straight Threaded

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free