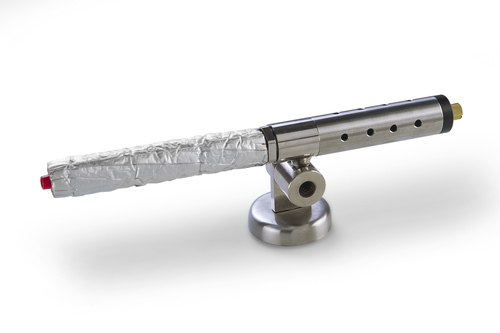

Compressed Air Saving Chip Shield Gun

Compressed Air Saving Chip Shield Gun Specification

- Air Discharge

- High Efficiency Jet Stream

- Noise Level

- <85 dB

- Condition

- New

- Material

- Stainless Steel & High-Impact Polycarbonate

- Power Source

- Compressed Air

- Dimensions

- Standard Ergonomic Size

- Lubrication Type

- Oil-Free

- Configuration

- Chip Shield Gun with Air Saving Nozzle

- Mute

- No

- Air Flow Capacity

- Optimized (Compressed Air Saving Design)

- Driven Method

- Manual (Handheld)

- Mounting Type

- Handheld

- Chip Guard Material

- Impact-Resistant Polycarbonate

- Handle Type

- Ergonomic, Anti-Slip

- Color

- Blue & Transparent

- Connection Port Size

- 1/4" NPT

- Weight

- Approx. 320 grams

- Operating Temperature

- 5°C to 60°C

- Application

- Machining, CNC Chip Removal, Industrial Cleanup

- Nozzle Type

- Venturi Air Saving Nozzle

- Safety Feature

- Transparent Chip Shield for Operator Protection

Compressed Air Saving Chip Shield Gun Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Compressed Air Saving Chip Shield Gun

When compressed air blown in machine shop on a job having scattered chip, operators are subject to severe risk of getting injured with Ricocheting chips.First of all ordinery compressed air blow guns are not recommended to be used in shop floor as dead end pressure of such guns exceeds 2 bar (28 PSI), secondly they waste huge amount of compressed air and thirdly ordinery blow guns - though available cheap are prone to leakage, not repairable and made from cheap grade plastics. Hence require frequent replacement.

General Imsubs are domestic manufacturer of premium grade, repairable (assured spare support) and air amplifying blow guns which can save 20% to 80% of compressed air.

Chip Shield guns are provided with unbreakable polycarbonte shield which stops Ricocheting chips / particles and deflect it away from operator. Hence providing safe work place.

Chip shield guns are prefered be management.

Efficient Chip Removal and Air Savings

Engineered with a specialized Venturi nozzle, this Chip Shield Gun maximizes compressed air usage, leading to significant energy savings. The high-efficiency jet stream ensures quick debris cleanup in machining and CNC applications while minimizing air wastage, supporting a sustainable and cost-effective process.

Unmatched Safety and Durability

Equipped with a transparent, impact-resistant polycarbonate shield, the tool offers clear visibility and robust protection for operators against flying chips and debris. Stainless steel components add to the guns longevity, making it suitable for long-term industrial use.

Operator Comfort and Flexible Application

Feature-rich with an ergonomic and anti-slip handle, this manually operated chip shield gun provides comfort during extended use. Its lightweight, portable design ensures easy maneuverability for use in various machining, cleanup, and workshop settings.

FAQs of Compressed Air Saving Chip Shield Gun:

Q: How does the Venturi Air Saving Nozzle reduce compressed air consumption?

A: The Venturi Air Saving Nozzle utilizes a design that mixes ambient air with compressed air, generating a high-volume jet using less compressed air. This results in efficient chip and debris removal while significantly reducing air consumption, lowering energy expenses.Q: What are the main benefits of the transparent chip guard made from impact-resistant polycarbonate?

A: The transparent chip guard protects the operator from flying debris and chips without obstructing visibility of the work area. Constructed from impact-resistant polycarbonate, it provides both safety and durability in demanding industrial environments.Q: When and where is this chip shield gun most effectively used?

A: This tool is ideal for use during CNC machining, chip removal, and general industrial cleanup tasks. Its rugged construction and safety features make it suitable for machine shops, manufacturing plants, and any application requiring fast and secure debris clearance.Q: What is the correct process for operating the chip shield gun?

A: Connect the gun to a compressed air source using the 1/4" NPT port, adjust to operate within the 5C to 60C temperature range, and grip the ergonomic handle securely. Aim the nozzle at the area to be cleaned, using the trigger to direct the air jet for chip or dust removal.Q: How does the ergonomic, anti-slip handle benefit the operator during prolonged use?

A: The ergonomic shape and anti-slip surface of the handle ensure a comfortable and secure grip, reducing hand fatigue and enabling precise control during long or repetitive operation.Q: What kind of maintenance does this chip shield gun require?

A: Minimal maintenance is required due to its oil-free, rugged design. Periodically inspect the chip shield and nozzle for residue or damage, and clean as necessary to ensure optimal performance and clear visibility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Blow Gun Category

Dry Machining Cold Air Gun

Price 15000.00 INR / Piece

Minimum Order Quantity : 15 Pieces

Condition : New

Dimensions : 250 mm (Length) x 40 mm (Diameter) approx.

Mute : Yes (Low Noise Design)

Configuration : Portable / Benchtop

CO2 Charging Gun

Price 3500.00 INR / Piece

Minimum Order Quantity : 80 Pieces

Condition : New

Dimensions : 370 mm (Length) x 110 mm (Height) x 60 mm (Width)

Mute : Yes

Configuration : Handheld

Dunnage Bag Inflator G-un

Price 3400 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Dimensions : 34 cm x 15 cm x 4 cm

Mute : Yes

Configuration : Ergonomic Handle with Air Control

Coolant Gun

Price 4500 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Dimensions : 200 mm x 30 mm x 80 mm

Mute : No

Configuration : Handheld

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free