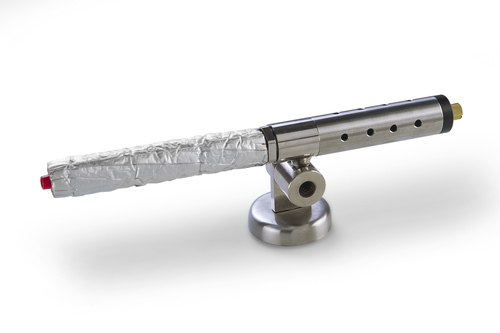

Dry Machining Cold Air Gun

Price 15000.00 INR/ Piece

Dry Machining Cold Air Gun Specification

- Power Consumption

- No Electrical Power Required

- Air Discharge

- Cold Air Stream, Adjustable

- Noise Level

- <80 dB(A)

- Condition

- New

- Material

- Aluminum Alloy

- Power Source

- Compressed Air

- Dimensions

- 250 mm (Length) x 40 mm (Diameter) approx.

- Lubrication Type

- Oil-Free

- Configuration

- Portable / Benchtop

- Mute

- Yes (Low Noise Design)

- Air Flow Capacity

- 300-1500 L/min

- Driven Method

- Compressed Air

- Working Presssure

- 5-7 Bar

- Maintenance

- Virtually Maintenance-Free

- Mounting Type

- Magnetic Base (Optional)

- Application

- Metal Cutting, Grinding, CNC Machining, Dry Machining

- Nozzle Type

- Directional, Swivel Adjustable

- Outlet Temperature Range

- As Low As -35°C

- Environment Friendly

- Yes, No Chemical Coolants or Lubricants Used

- Usage

- Ideal for Dry Machining to Eliminate Mist and Coolant

- Hose Length

- 1.5 m Standard Hose Included

- Weight

- Approx. 1.2 kg

- Cooling Capability

- Cools Air Down to 20-30°C Below Ambient

Dry Machining Cold Air Gun Trade Information

- Minimum Order Quantity

- 15 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Dry Machining Cold Air Gun

Cold air gun utilized vortex tube to provide dry cool air for spot cooling dry machining and many other such application.

Cold air guns utilizes available compressed air on shop floor and gives stream of cold air which could have temperature 40oC lower than input compressed air temperature.

Cold air guns has no moving parts hence practically zero maintenance. Its magnetic base allows quick and easy installation

Cold air guns are known to increase tool life and machining speed while machining plastics, brass, wood and other material which must be machined dry.

Features:

- Instant installation and portable, can be shifted to machine instantly.

- Adjustable cold fraction hence adjustable cold air temperature.

- Flexible, stay put hose for precise targeting of cold air.

- Two outlet hose hoses available against specific orders.

- Dramatically increases tool life and improves tolerances.

- Cold air stream blow off cheap hence post cleaning may not be needed.

Application:

- Dry Machining of plastic, brass and composite materials.

- Grinding, drilling and sharpening operations.

- Mold, dies cutting edge cooling.

- Cooling of adhesive, solders and weld seams.

- Spot cooling requirements.

|

MODEL |

CAG-002 |

CAG -004 |

CAG -008 |

CAG -010 |

CAG -015 |

CAG -025 |

CAG -030 |

CAG -040 |

|

CFM |

2 |

4 |

8 |

10 |

15 |

25 |

30 |

40 |

|

LPM |

57 |

113 |

226 |

285 |

425 |

710 |

850 |

1135 |

|

BTU/Hr |

120 |

215 |

500 |

600 |

900 |

1500 |

2000 |

2800 |

|

Kcal/Hr |

30 |

55 |

125 |

150 |

225 |

380 |

500 |

700 |

All General Imsubs blow guns are made from tough, heat treated engineering plastics, which last for years and also they are repairable. Hence in case of leakage or other problems, customer need not to discard blow guns.

General Imsubs guns are leak resistant and user guide is provided with part list for easy ordering.

General Imsubs valves are warranted against manufacturing defects and are supplied with assured spare support.

Efficient Cooling for Dry Machining Processes

Achieve superior temperature control during metal cutting, grinding, and CNC machining. The Cold Air Gun efficiently cools the air stream up to 20-30C below ambient, ensuring improved workpiece integrity and tool life without introducing mist, coolant, or lubricants.

Eco-Friendly and Maintenance-Free Operation

Designed for environmentally conscious workplaces, this air gun eliminates chemical coolants and operates oil-free. Its virtually maintenance-free design helps minimize downtime and ensures reliable, consistent cooling with a low noise profile, enhancing shop safety and comfort.

Flexible Mounting and Easy Configuration

With a standard 1.5-meter hose and optional magnetic base, this Cold Air Gun adapts to benchtop or portable setups. Its lightweight build and swivel-adjustable nozzle simplify installation and adjustment, making it perfect for various industrial environments and machine types.

FAQs of Dry Machining Cold Air Gun:

Q: How does the Dry Machining Cold Air Gun operate without using chemical coolants or lubricants?

A: The Cold Air Gun uses compressed air to generate a high-velocity cold air stream, cooling workpieces during machining, grinding, or cutting. This process eliminates the need for chemical coolants or lubricants, promoting cleaner operations and reducing environmental impact.Q: What are the recommended applications for this Cold Air Gun in manufacturing?

A: This air gun is ideal for metal cutting, grinding, dry machining, and CNC machining processes, where effective cooling is needed to protect both workpieces and tooling while keeping operations oil-free and mist-free.Q: When is it necessary to use the magnetic base for mounting the Cold Air Gun?

A: The optional magnetic base is recommended when you require stable, hands-free operation or need to position the air gun securely on metallic surfaces near the machining area. This feature is especially helpful for repetitive tasks or precision setups.Q: Where can the Cold Air Gun be installed for optimal performance?

A: It can be configured for benchtop or portable use, thanks to its compact size and lightweight design. The 1.5-meter standard hose allows flexible positioning near machines or workpieces, while the directional nozzle ensures targeted cooling.Q: What maintenance is required for this Cold Air Gun, and is it truly maintenance-free?

A: The air guns oil-free, simple design requires virtually no regular maintenance apart from checking the hose and nozzle for blockages. Its robust aluminum alloy construction and lack of moving electrical parts minimize downtime and upkeep.Q: How does adjustable cold air flow benefit dry machining processes?

A: The ability to adjust the cold air stream in terms of direction and flow allows precise control over cooling, preventing thermal deformation and improving both tool longevity and surface finish. This enhances productivity and quality in dry machining applications.Q: What are the environmental and operational advantages of using this Cold Air Gun?

A: By eliminating chemical coolant use, it reduces hazardous waste, keeps the workspace cleaner, and lowers operational costs. Its low noise design improves shop comfort, and the oil-free operation supports sustainable manufacturing practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Blow Gun Category

Ergonomic Gun

Price 3400.00 INR / Piece

Minimum Order Quantity : 80 Pieces

Condition : New

Material : ABS Plastic and Metal Alloy

Noise Level : Less than 70 dB

Chip Shield Gun

Price Range 3400.00 - 5000.00 INR / Paint

Minimum Order Quantity : 1 Piece

Condition : New

Material : Aluminum alloy (body); Polycarbonate (shield)

Noise Level : <85 dB(A)

CO2 Charging Gun

Price 3500.00 INR / Piece

Minimum Order Quantity : 80 Pieces

Condition : New

Material : HighQuality Stainless Steel & Brass Components

Noise Level : Low / Silent

Compressed Air Saving Chip Shield Gun

Price Range 3400.00 - 7000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Material : Stainless Steel & HighImpact Polycarbonate

Noise Level : <85 dB

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free