Straight Valve BSP Male threads

Price 200 INR/ Piece

Straight Valve BSP Male threads Specification

- Noise Level

- Silent Operation

- Condition

- New

- Material

- Brass/Nickel Plated Brass

- Dimensions

- 1/4 to 2 BSP Male Threads

- Configuration

- Straight Valve

- Mute

- Yes

- Driven Method

- Manual

- Working Presssure

- Up to 16 Bar

Straight Valve BSP Male threads Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Straight Valve BSP Male threads

Straight Valve BSP Male Threads are fastening threads and require the use of a gasket or cone seal. Also known as British Standard Pipe Fitting thread and British Standard Pipe Mechanical thread, these threads have a constant diameter, denoted by the letter G. Also, these are adopted as standard in plumbing and pipe fitting. The most common Straight Valve BSP Male Threads are tapered with pressure tight joints achieved by the threads. Clients can avail these threads from us in varied specifications.

Features:

- Easy to install

- Abrasion resistant

- Robust design

Reliable Manual Control for Multiple Media

Equipped with a precision metal lever handle, this straight valve allows for dependable manual regulation of air, water, oil, and gas. Its mute feature guarantees silent operation, making it suitable for noise-sensitive environments. Built to withstand routine use, the valve offers smooth switching and uncompromised sealing for process integrity.

Durability and Corrosion Resistance

Manufactured from high-grade brass and available with a corrosion-resistant nickel-plated finish, this valve ensures enduring performance even in challenging environments. Its construction supports extended temperature ranges (-10C to 80C) and provides resistance against wear, making it optimal for both new installations and replacement needs.

FAQs of Straight Valve BSP Male threads:

Q: How do I install a Straight Valve BSP Male Thread in my system?

A: To install, ensure the valve size matches your piping, apply PTFE tape or appropriate sealant to the BSP male threads, and screw it onto the female coupling. Tighten securely using suitable tools. Check for leaks upon completion and operate the metal lever to test flow control.Q: What types of fluids and gases can the valve handle?

A: The valve is designed for compatibility with air, water, oil, and various gases. Its robust brass or nickel-plated brass construction and PTFE/NBR seal type ensure reliable performance with these media, supporting pressures up to 16 Bar.Q: When should I consider using a nickel-plated surface finish?

A: Choose the nickel-plated finish if your installation is exposed to moisture, chemicals, or corrosive atmospheres. The plating offers enhanced resistance against corrosion and wear, contributing to longer-lasting service in demanding environments.Q: Where is this valve best suited for installation?

A: This valve is ideal for industrial, commercial, and residential sectors where air, water, oil, or gas flow requires manual control. Its silent operation and high-pressure rating make it suitable for systems in factories, workshops, process plants, and utility setups.Q: What is the process for maintaining the Straight Valve BSP Male Thread?

A: Regularly inspect the valve for any signs of leaking, corrosion, or compromised operation. Ensure the handle moves freely and the sealing remains intact. Periodic cleaning and tightening help maintain optimal performance and extend service life.Q: What are the key benefits of using this straight valve?

A: The major benefits include silent operation, robust corrosion resistance, high-pressure capacity up to 16 Bar, versatile connection compatibility, and reliability for various fluids and gases. The manual lever ensures easy flow adjustment, while quality materials provide durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Solenoid valves Category

I-30F-M-F Solenoid Valve

Price 7500.00 INR / Piece

Minimum Order Quantity : 40 Pieces

Configuration : 2/2 Way

Dimensions : Body Length 103 mm x Width 40 mm x Height 80 mm

Mute : No

Driven Method : Electrically Operated

Straight magnetically latching valve

Price 350 INR / Piece

Minimum Order Quantity : 10 Pieces

Configuration : Straight (inline)

Dimensions : Varies as per model (e.g., 45 x 25 x 21 mm)

Mute : Yes

Driven Method : Electromagnetic

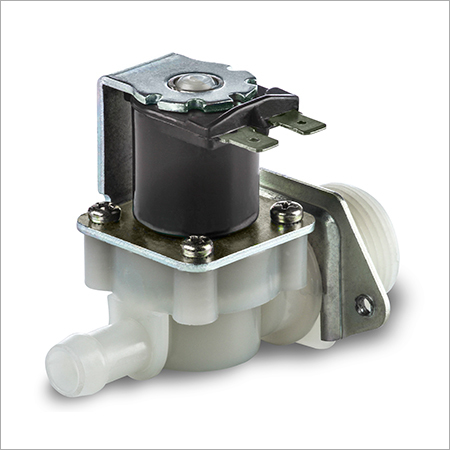

Whirlpool Washing Machine Inlet Solenoid Valve

Price 200 INR / Piece

Minimum Order Quantity : 1 Piece

Configuration : 2 Way Inlet Valve

Dimensions : Approx. 90mm x 60mm x 45mm

Mute : Yes

Driven Method : Electromagnetic Actuation

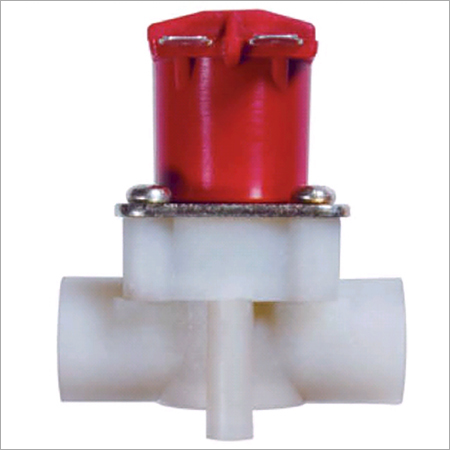

Ro System Inside Threaded Solenoid Valve

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Configuration : 2 Way Normally Closed

Dimensions : About 60mm x 22mm x 40mm

Mute : Yes

Driven Method : Electromagnetic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free